Essential Spare Parts for AB Switches (Isolators)

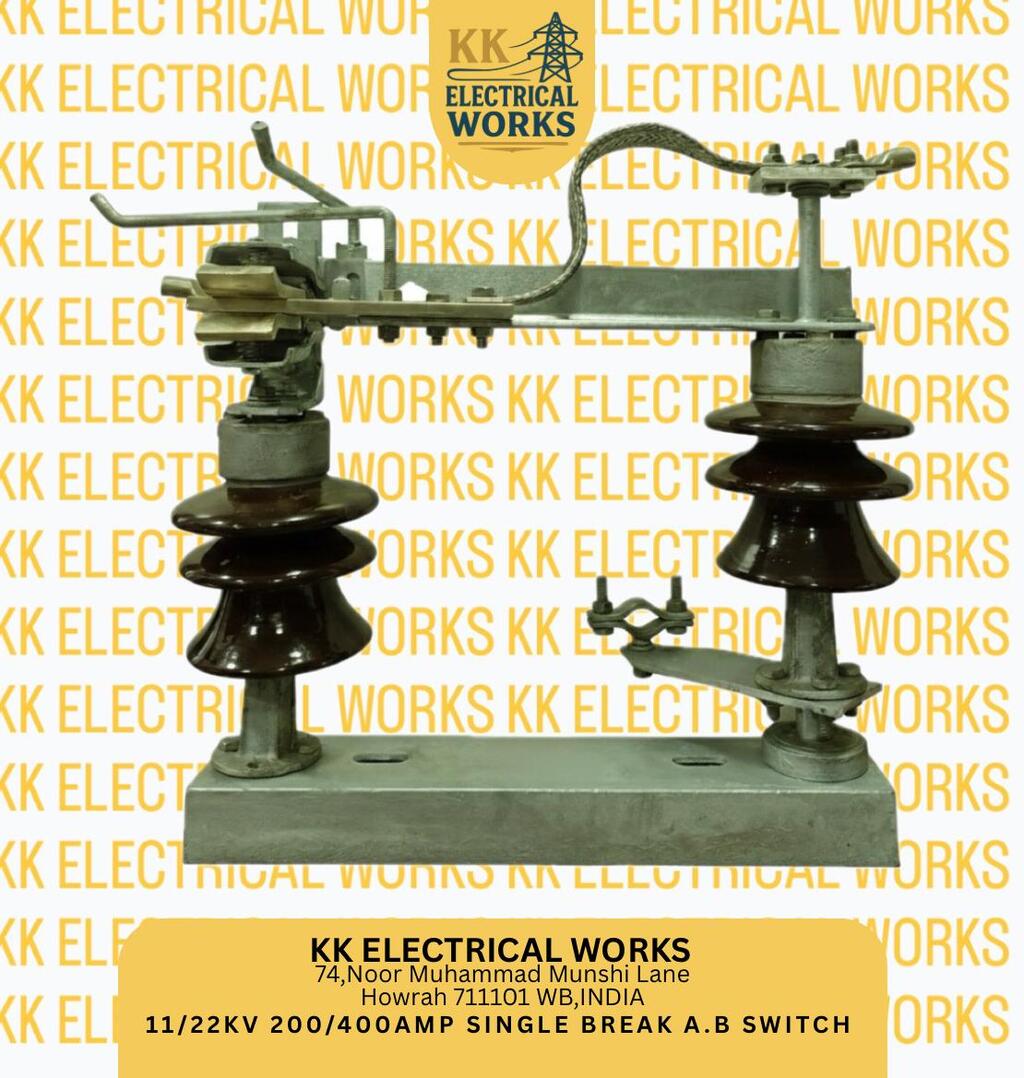

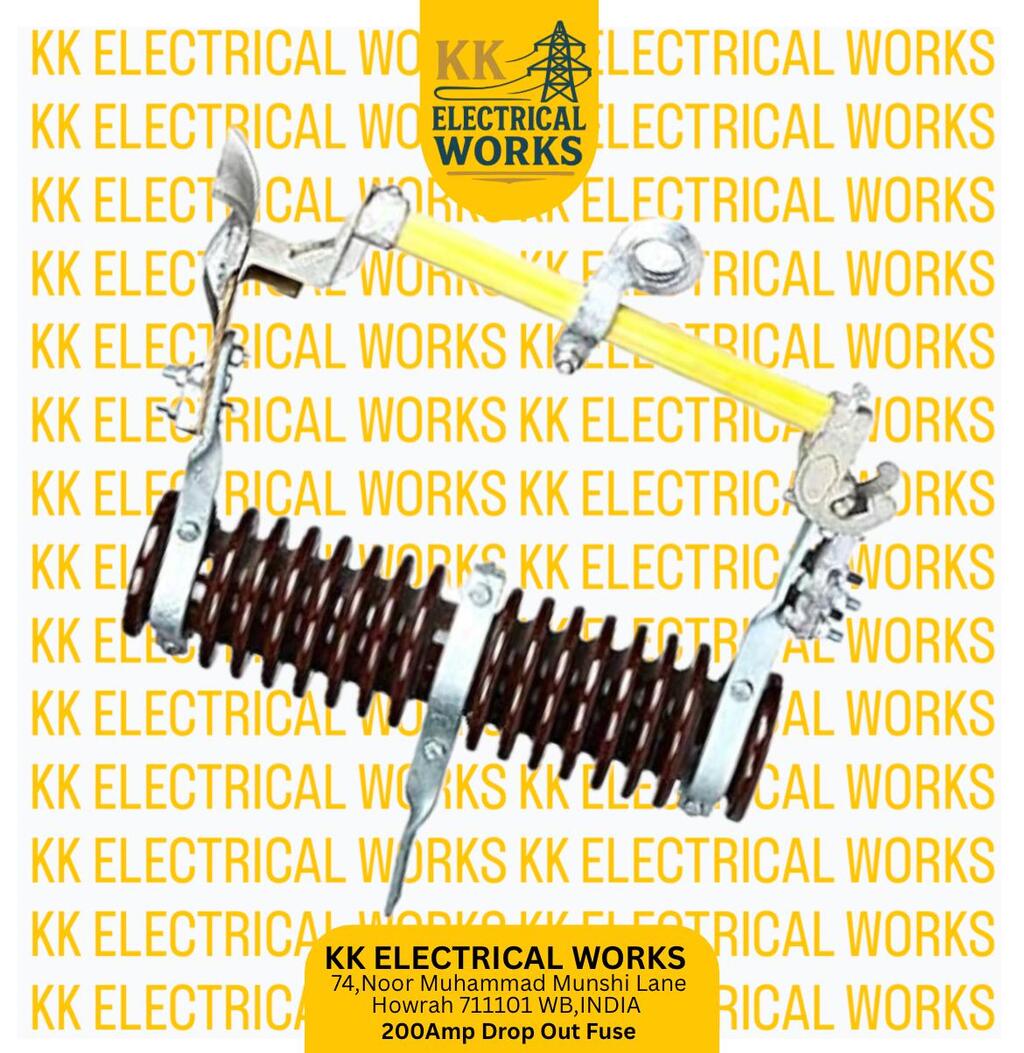

The Air-Break Switch (AB Switch), or disconnector, is a robust mechanical device, but its constant exposure to the elements and mechanical operation means certain components require periodic maintenance or replacement. Since the AB switch's main role is to provide a visible, secure break, the spare parts often relate to its mechanical movement and current-carrying capabilities.

Key spare parts for an AB Switch include:

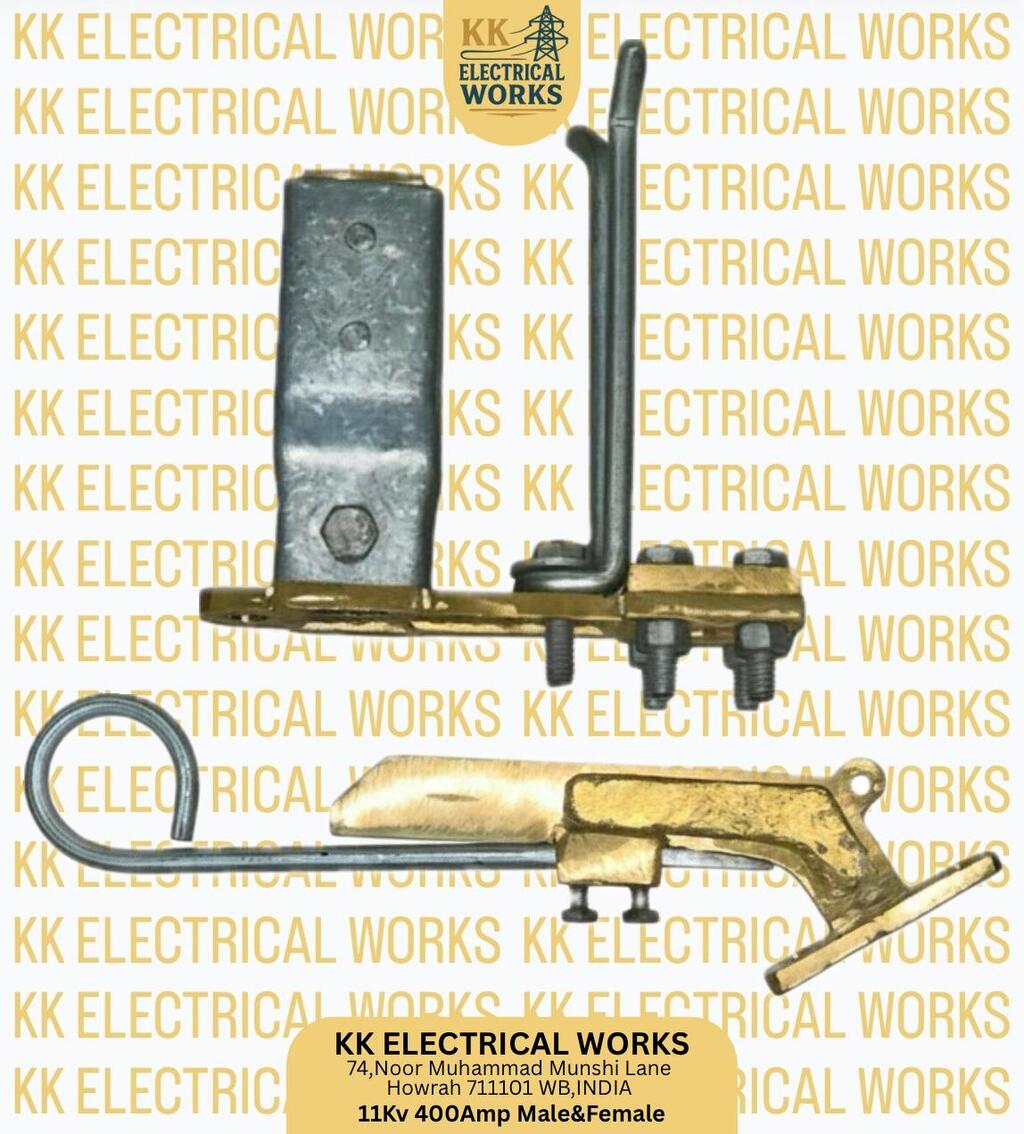

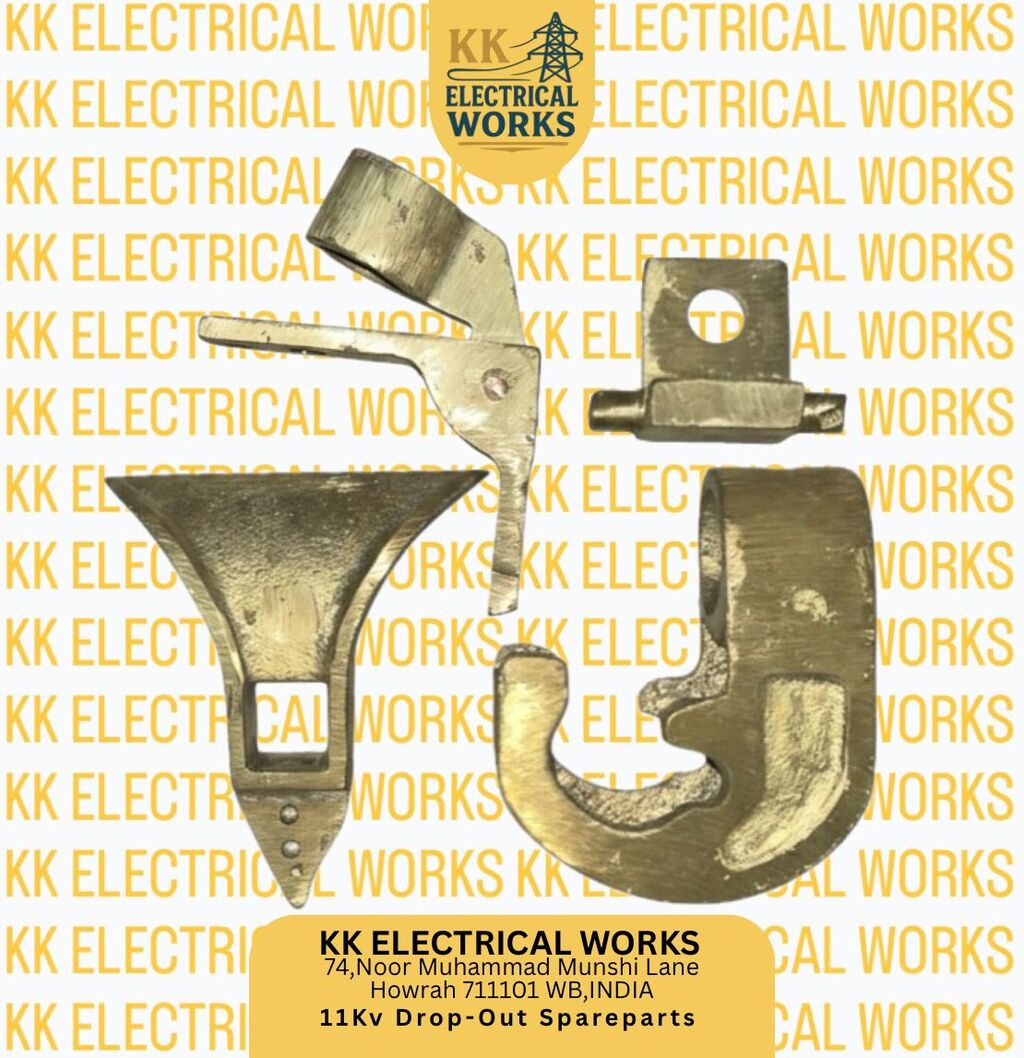

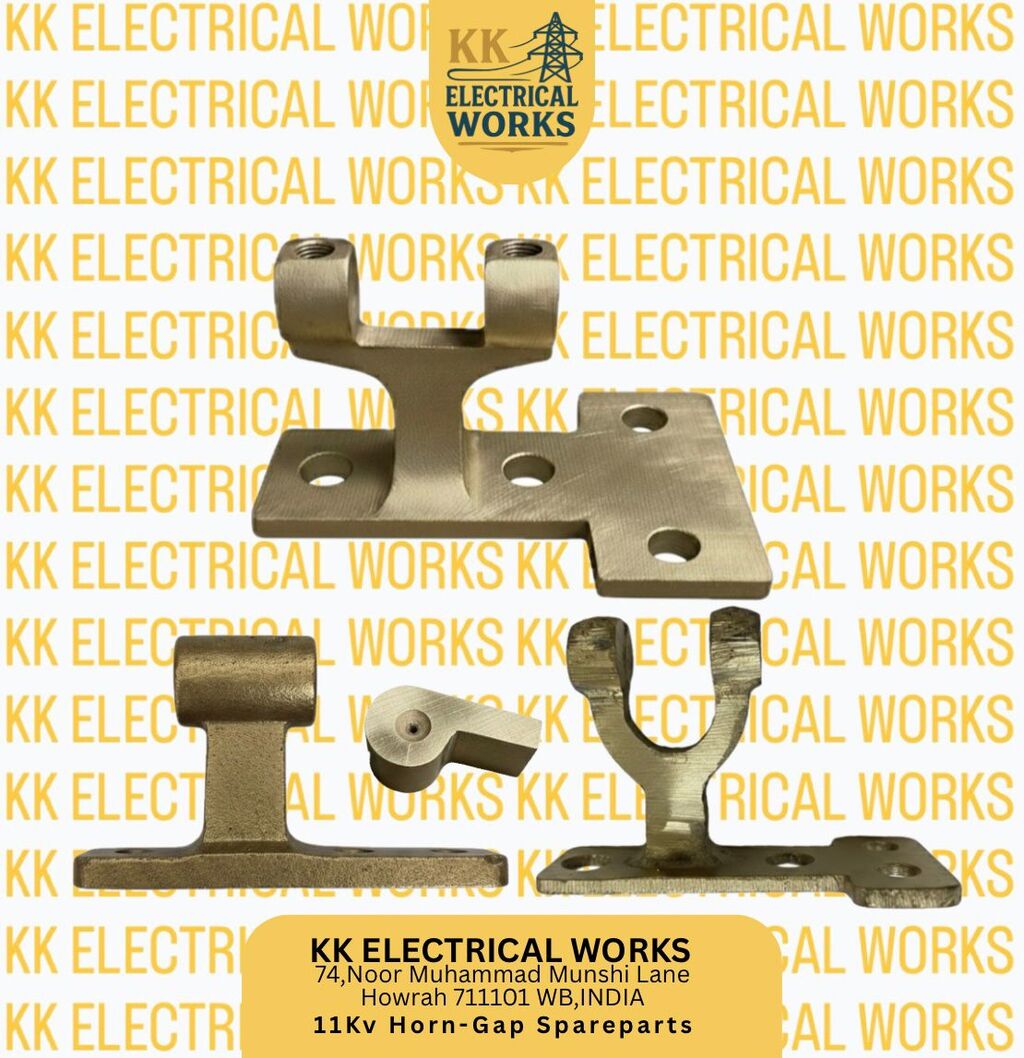

• Contacts (Male and Female): These are the most critical current-carrying components. They are typically made of high-conductivity materials like copper or brass, often silver-plated or tinned for improved conductivity and corrosion resistance. Over time, arcing (if the switch is operated under load accidentally) or wear and tear can degrade these parts, requiring replacement.

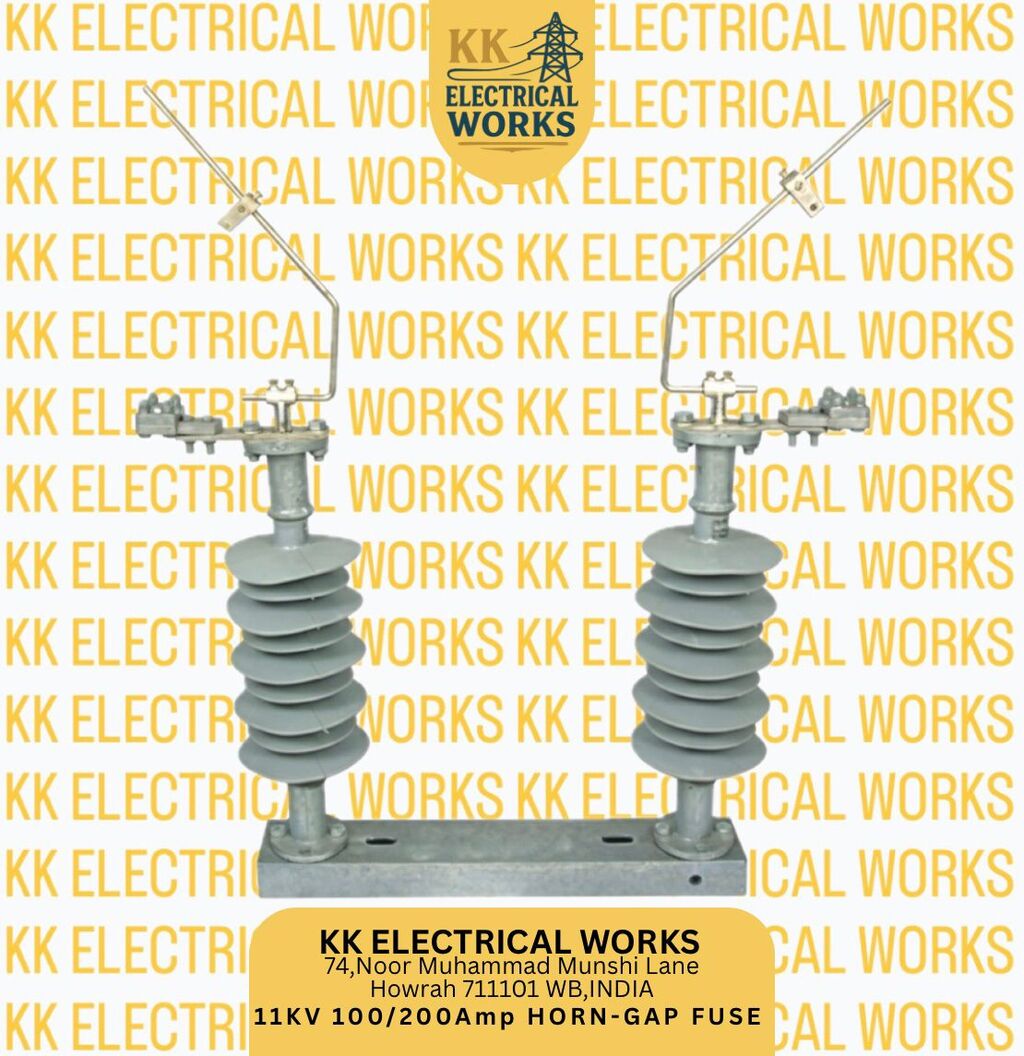

• Insulators: These provide the necessary electrical isolation. They can be made of porcelain (traditional) or polymer/composite (modern, lighter, and more resistant to vandalism/breakage). While durable, they can fail due to physical damage or flashover, and spare units are essential for quick repair.

• Operating and Bearing Mechanisms: This includes the bearing housing (often Mild Steel and galvanized), operating handles/levers, and linkage rods (like the square or tubular operating pipe). These mechanical parts ensure smooth, gang-operated movement across all three phases and are replaced when rust, wear, or misalignment occurs.

• Flexible Jumpers (Copper Braids): These are flexible copper connections used to carry current between moving and fixed parts without restricting motion. They can fray or break due to vibration and fatigue.